SUCCESS IN EVERY HARDNESS

Elevate Your Feeding Experience with Sallent: Superior Durability, Precision Engineering, and Unmatched Efficiency.

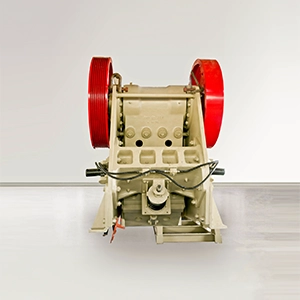

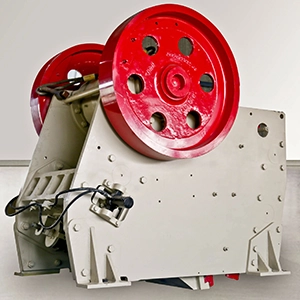

Robust Main Frame Assembly

Fabricated from steel plate for maximum durability and impact rigidity, ensuring long-lasting performance without excess weight.

Specially Designed Coil Springs

Absorb impact loads and eliminate transmission of vibration and shock loads, enhancing stability and reliability.

Abrasion-Resistant Pan and Side Plate Liners

Bolt-on design for easy maintenance, featuring 12mm thick liners for prolonged durability and simplified upkeep.

Heavy-Duty Twin Shaft Drive Mechanism

Supported by grease-lubricated spherical roller bearings for increased load-carrying capacity and extended life.

Oil-Bath Lubricated Gears

Drive mechanism with twin shafts connected through gears immersed in oil, resulting in self-synchronizing linear motion.

Adjustable Amplitude

Forged alloy steel plain shafts with threaded holes for counterweights, allowing amplitude adjustment for optimal performance.

Variable Speed Drive

Electric motor and V-belt drive arrangement with the option of using VFD for speed and feed rate variation, ensuring versatility and adaptability.

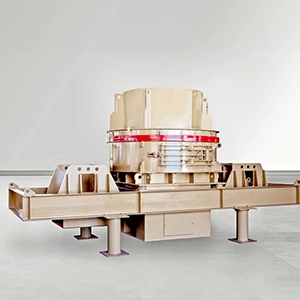

Cassette-Type Grizzly Bar Deck

Designed with tapered openings and welded abrasion-resistant liner cover for improved scalping efficiency and reduced pegging.

Bolt-On Bottom Deck

Facilitates efficient scalping of finer material, enhancing overall screening performance and productivity.

Tensioned Screening Media

Utilizes steeper inclination for efficient removal of fines, optimizing material separation and throughput.

No more images available.

Technical specification

Core's Vibrating Grizzly Feeders seamlessly combine scalping and feeding functions, handling high volumes of materials for uniform, controlled feed, and optimizing crushing efficiency in any setup.

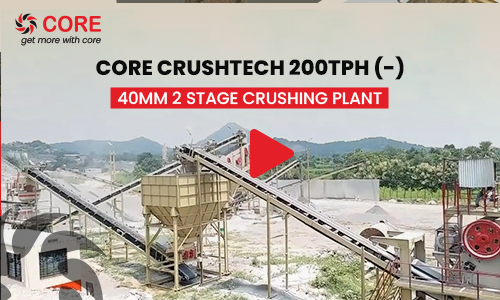

Video

Have a question? Talk to our expert!

Our team is here to assist you with any inquiries or concerns you may have. Contact us now to get the answers you need and make informed decisions for your project.

Gallery