SUCCESS IN EVERY HARDNESS

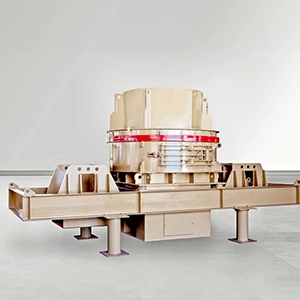

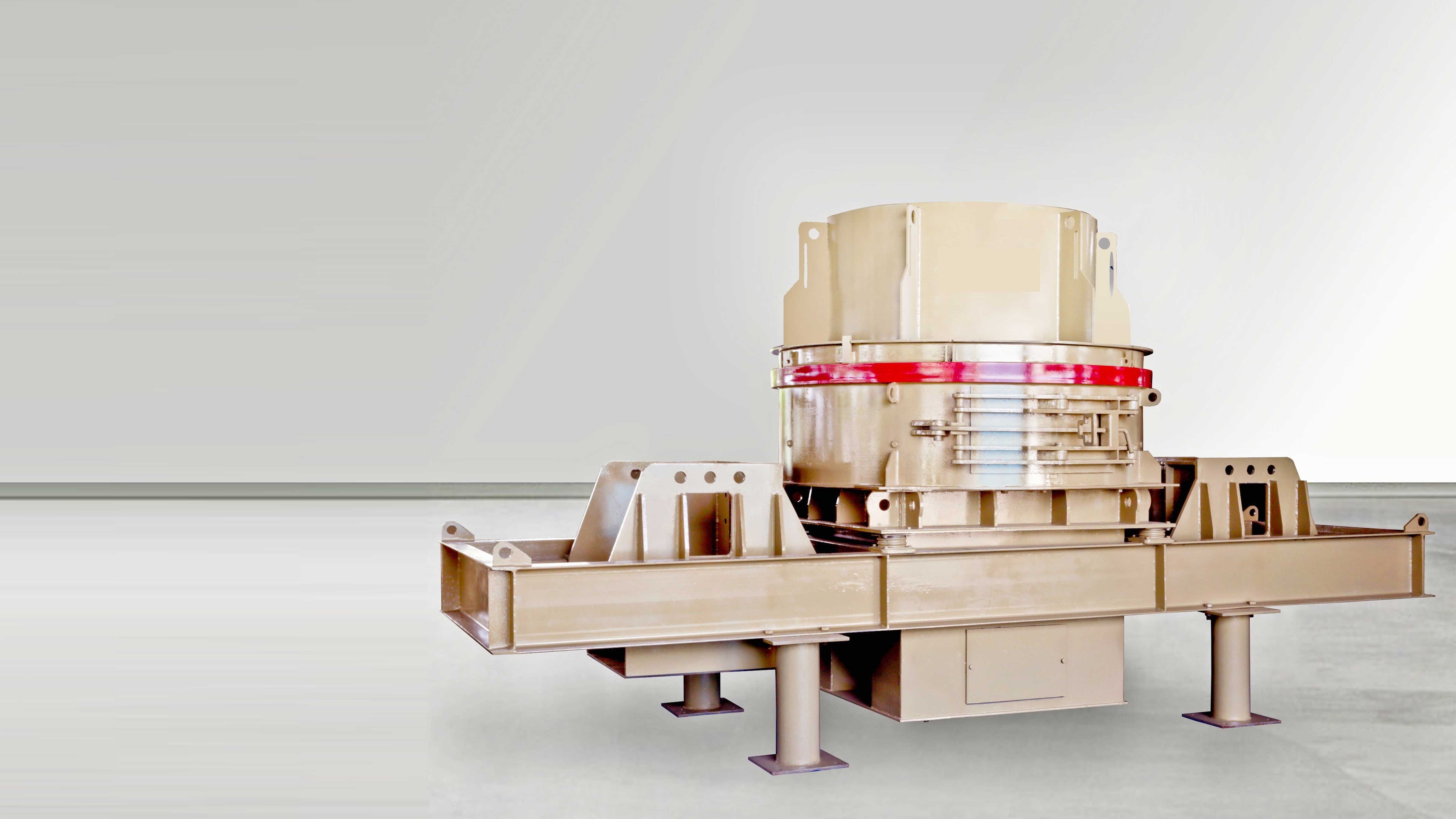

Optimized crusher design with high-grade steel rotor wears parts and tungsten carbide tips, balanced rotor for high-speed operation, bypass system for flexible plant layout, and oil lubrication panel for easy maintenance.

High-Quality Rotor Components

Utilizes premium steel and tungsten carbide tips for enhanced durability and reduced wear costs.

Automated Oil Lubrication

Advanced panel ensures efficient lubrication, minimizing maintenance compared to manual greasing.

Seamless High-Speed Operation

A well-balanced rotor design enables smooth operation at high speeds for optimized performance.

Top Shell Bypass System

Enhances operational flexibility and material handling efficiency.

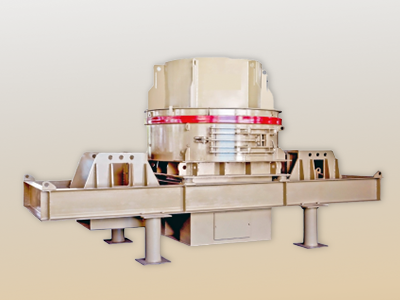

Improved Wear Resistance

Advanced materials and design minimize downtime and maintenance needs.

Efficient Lubrication

An automated system ensures consistent lubrication, prolonging equipment life and reducing breakdown risk.

Reliable Performance

Engineered for consistent and efficient operation in demanding conditions.

Simplified Maintenance

Streamlined procedures reduce downtime and enhance overall efficiency.

Versatile Application

Suitable for various materials and operating conditions, offering adaptability for different crushing needs.

Cost-Effective Solution

Reduces maintenance costs and prolongs equipment life, optimizing overall operational efficiency.

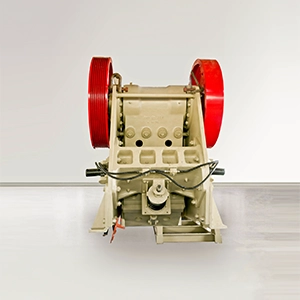

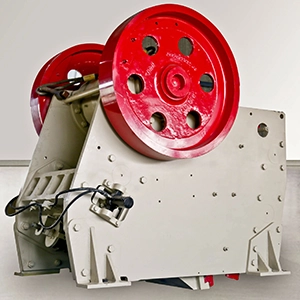

Technical specification

Advanced crusher design with durable rotor wear parts, balanced for high-speed operation.

Video

Have a question? Talk to our expert!

Our team is here to assist you with any inquiries or concerns you may have. Contact us now to get the answers you need and make informed decisions for your project.

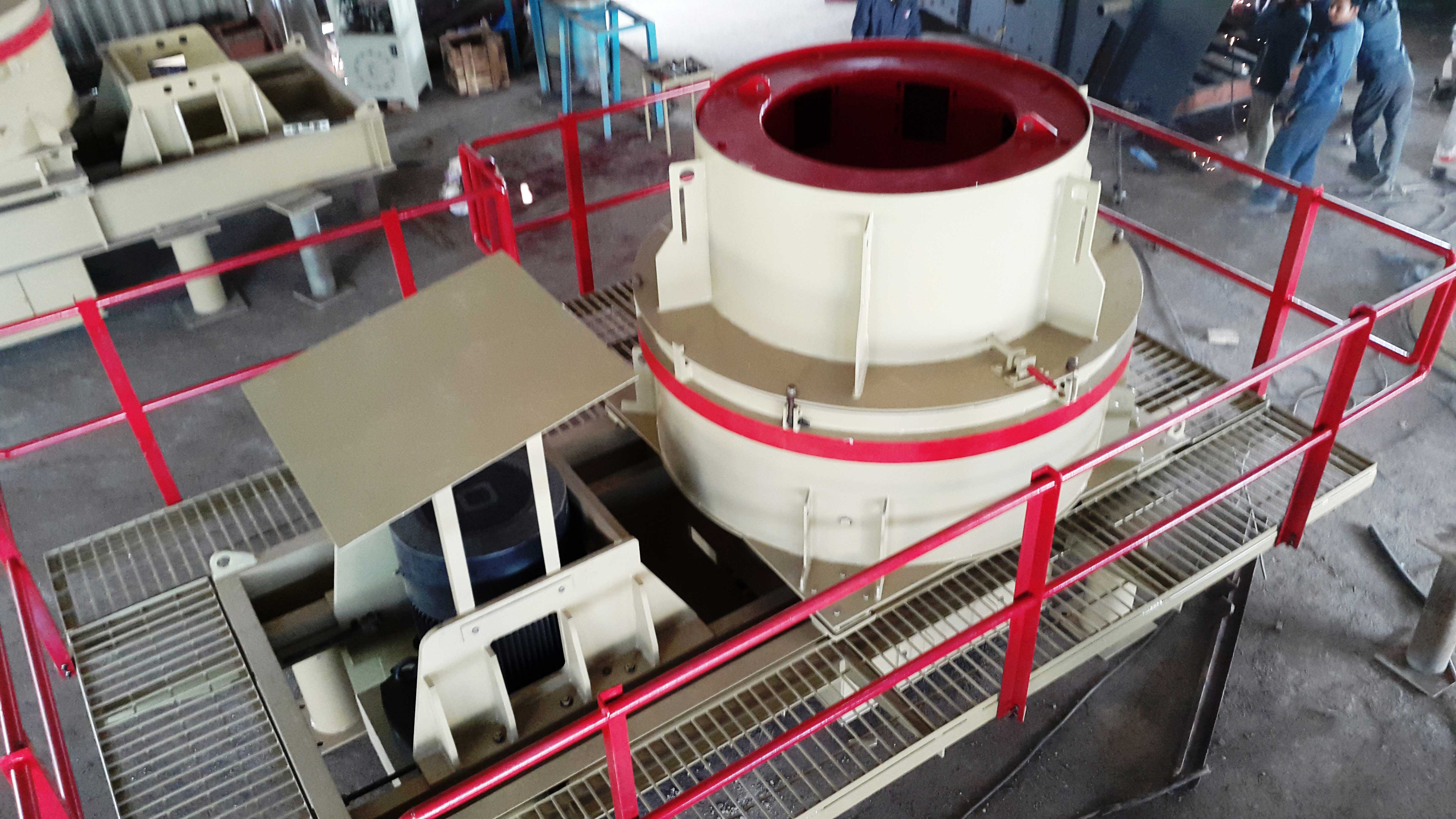

Gallery