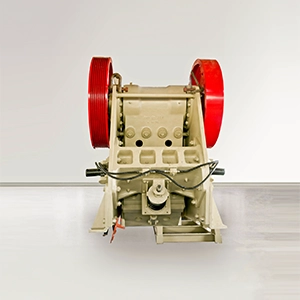

SUCCESS IN EVERY HARDNESS

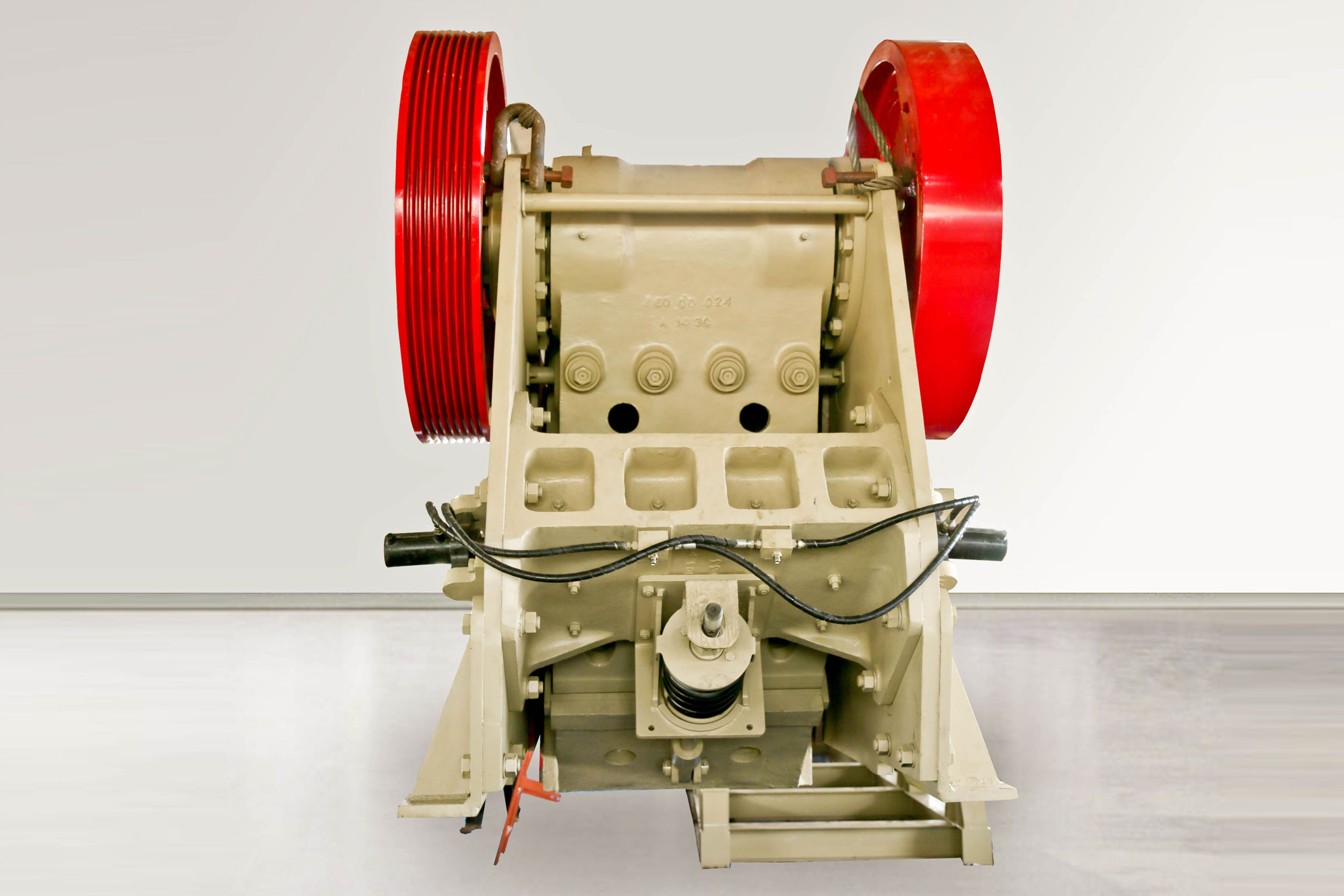

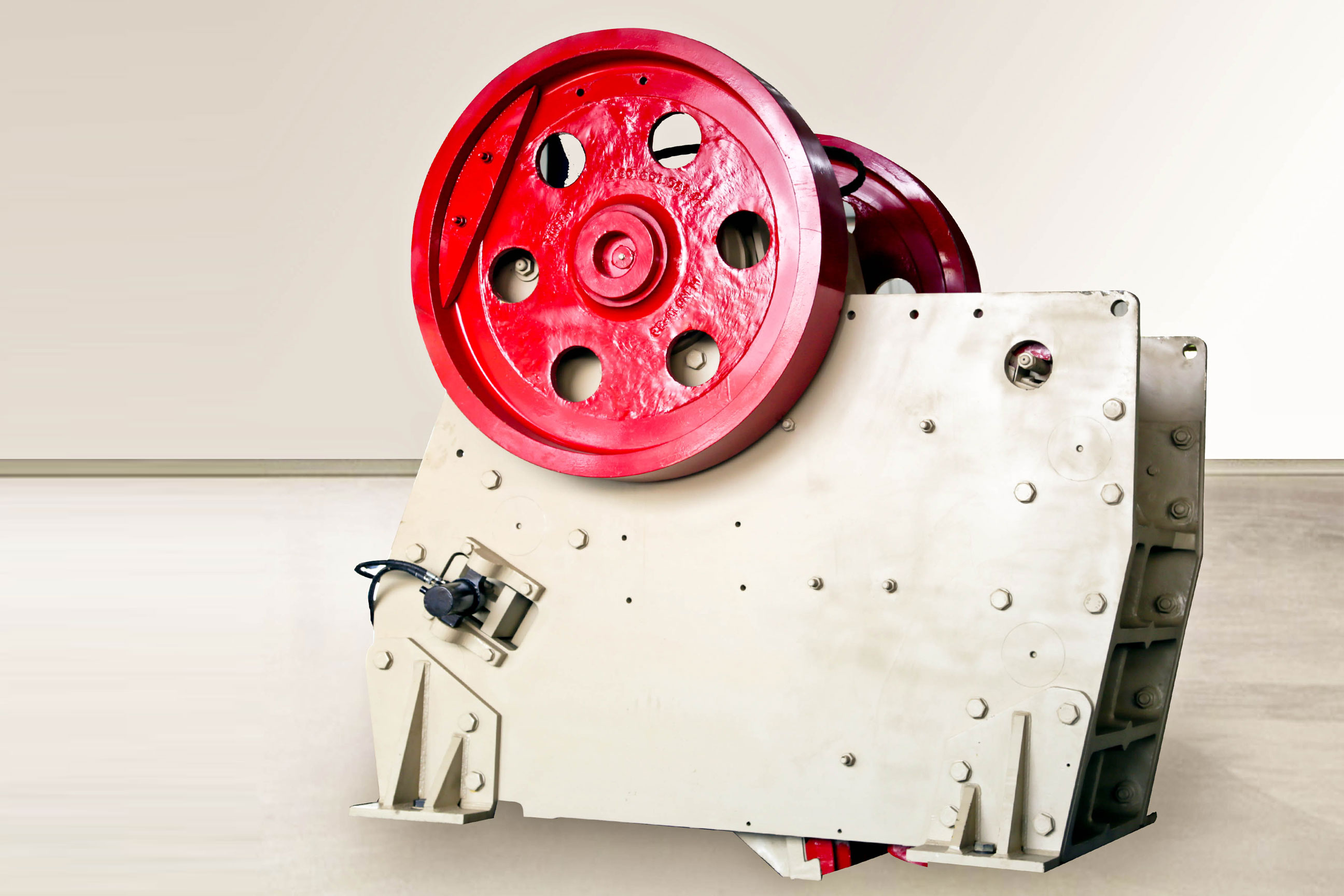

Core Crushing Jaw Crushers: Engineered for Efficiency, Built for Durability.

Automatic Wedge Adjustment

Hydraulic cylinders enable swift and effortless CSS/output size adjustment.

Reduced Wear Costs

Cast Hi Manganese construction in Fixed and Pitman jaw Dies minimizes wear expenses.

Steep Crushing Chamber

Enhances throughput capacity and improves crushing ratio with an aggressive elliptical stroke.

Four-Piece Bolted Design

Exclusively designed for easy assembly, eliminating the need for welding during setup.

Efficient Hydraulic System

Facilitates quick and precise adjustment, enhancing operational efficiency.

Durable Construction

Ensures longevity and reliability in demanding crushing applications.

Optimal Crushing Performance

Achieved through precision engineering and innovative design features.

Enhanced Safety

Bolted design eliminates potential welding hazards and ensures secure equipment assembly.

Cost-Effective Solution

Minimizes maintenance costs and downtime with its robust construction and efficient operation.

Versatile Applications

Suitable for a wide range of materials and crushing requirements, providing versatile performance.

Technical specification

Video

Have a question? Talk to our expert!

Our team is here to assist you with any inquiries or concerns you may have. Contact us now to get the answers you need and make informed decisions for your project.

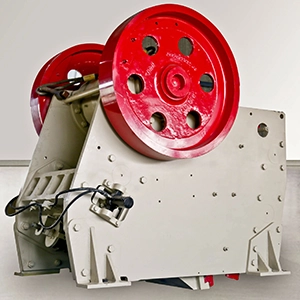

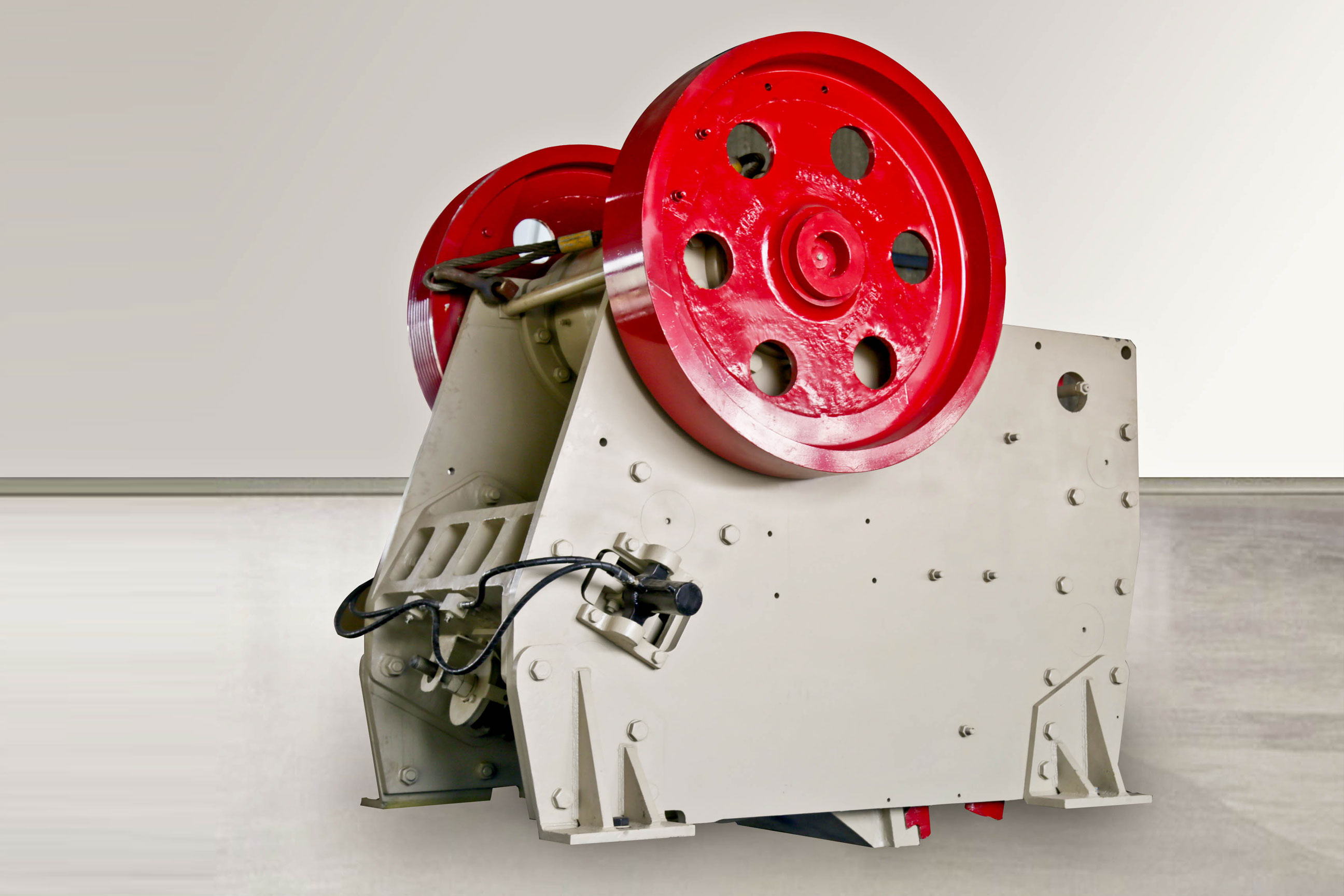

Gallery