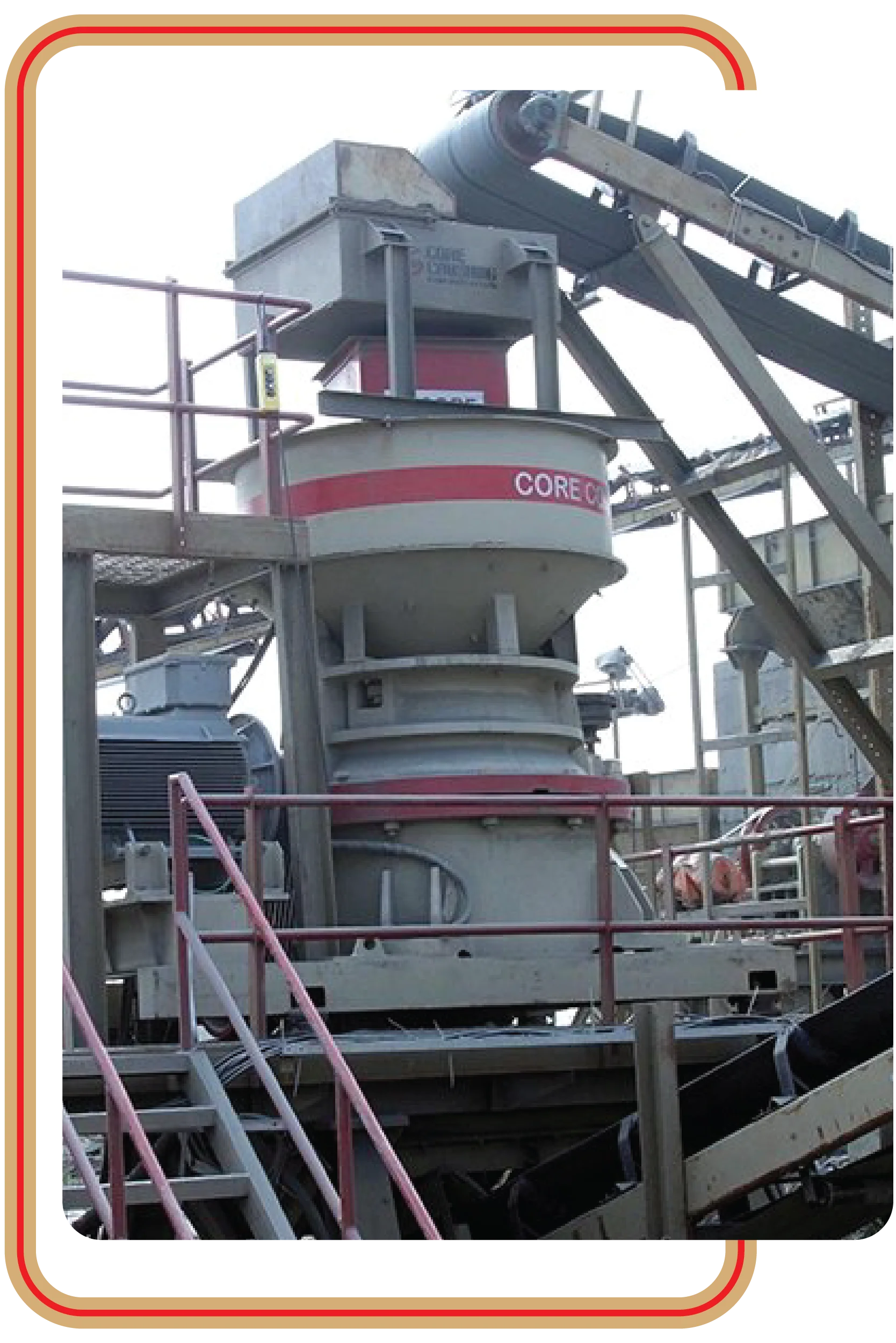

SUCCESS IN EVERY HARDNESS

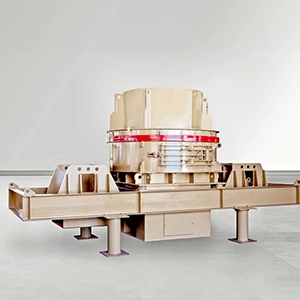

Revolutionizing Sand Production: Maximal Output, Minimal Power, Superior Quality.

Superior Aggregate Shape:

Engineered to produce well-rounded aggregates with reduced flakiness for improved quality.

Maximized Sand Production:

Achieves 70-80 TPH of sand output with minimal power consumption.

Single Motor Requirement:

Utilizes a 160 kW motor, unlike VSIs that demand dual motors of higher ratings.

Low Ultrafine Content:

Produced sand contains only 10% ultrafine particles, compared to >20% in conventional VSIs.

Direct Usage:

Sand requires no further treatment, such as water washing or air classification, making it ready for immediate use in RMC. .

Built-in Features:

Incorporates benefits from the SH series, including a rotary feed distributor for uniform distribution and a hydraulic power pack

Enhanced Efficiency:

Optimized design ensures efficient sand production with reduced energy consumption.

Reliable Performance:

Engineered for consistent sand output and quality, ensuring reliability in production.

Versatile Application:

Suitable for various sand production requirements, from construction to industrial applications.

Cost-Effective Solution:

Reduces operational costs with efficient sand production and minimal post-processing needs. .

Technical specification

Setting new standards in precision and performance.

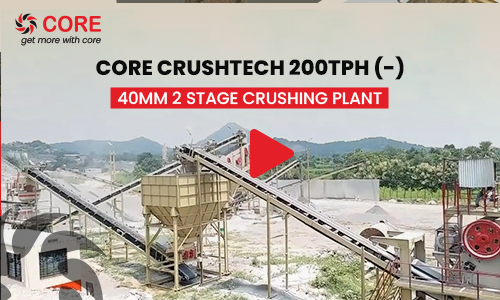

Video

Have a question? Talk to our expert!

Our team is here to assist you with any inquiries or concerns you may have. Contact us now to get the answers you need and make informed decisions for your project.

Gallery