Cone Crushers

Welcome to Crusher Solutions, where industry-leading innovation meets unparalleled performance.

Enquire NowSUCCESS IN EVERY HARDNESS

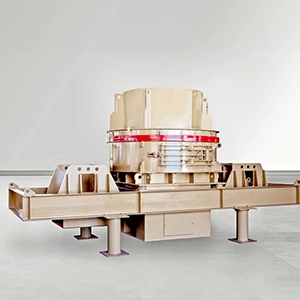

Core's SH Cone Crushers: Optimized for superior performance and durability in versatile crushing applications.

Cartridge-Type Design:

Allows easy access for inspection and servicing of components.

Compact and Balanced:

The counterbalance mechanism reduces out-of-balance forces, ensuring stability.

Speed Flexibility:

Roller bearing design enables flexible speed operation without limitations.

High Productivity:

Versatile usage options for secondary, tertiary, or quaternary crushing applications.

Combined Hydraulic Power Pack:

Facilitates lubrication, CSS adjustment, and tramp iron release for optimal operation.

Rugged Construction:

Cast top and bottom shells withstand crushing loads for durability.

Roller Bearing Design:

Lowers frictional losses, optimizing running HP and increasing available power for crushing.

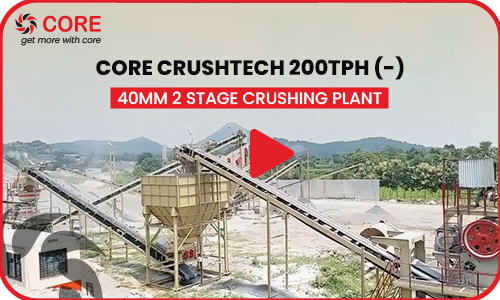

Video

Have a question? Talk to our expert!

Our team is here to assist you with any inquiries or concerns you may have. Contact us now to get the answers you need and make informed decisions for your project.

Gallery